30,000 Lb. Tow Motor Manipulator

30,000 Lb. Tow Motor Manipulator

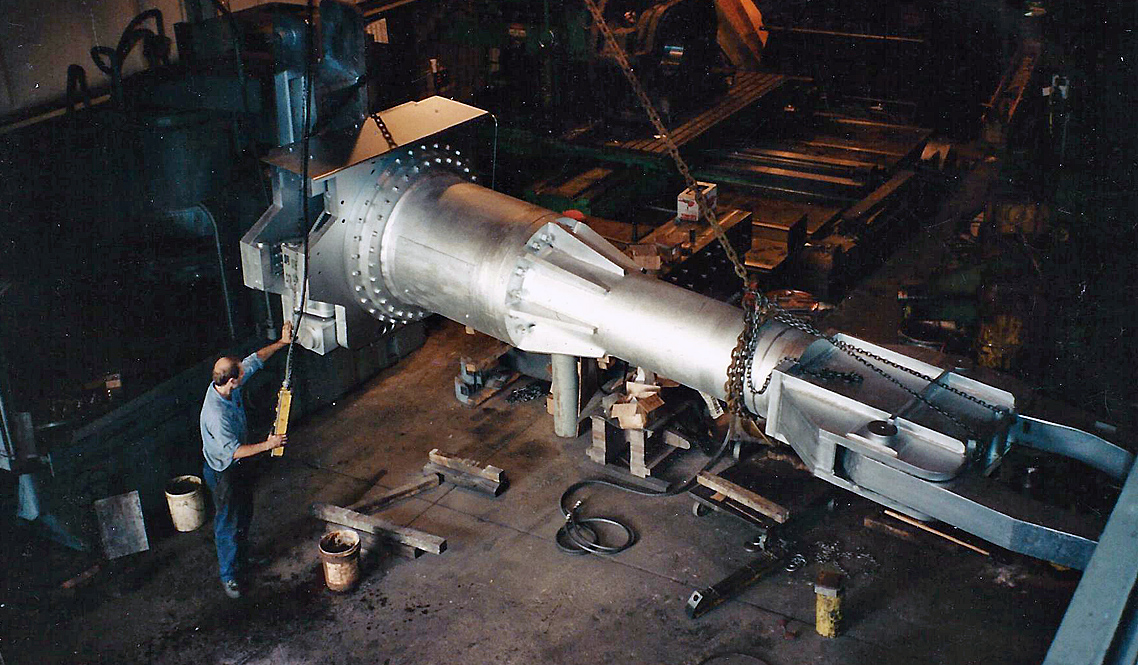

Kiefer Tool fabricated and machined a large steel component for ALCOA in Cleveland, Ohio. The tow motor manipulator is used for loading aluminum billets into a forging press. In 1995 Kiefer Tool & Mold built a new manipulator arm for ALCOA’s (Arconic, Inc.) 30,000 pound tow motor in their large press department. The manipulator arm was completely machined, fabricated and assembled in house including the gripper arms and pads, telescope body, gear box and rotor assemblies, and mounting plate. The project was the first of its kind to fully encompass the complete efforts of Kiefer Tool & Mold’s staff and equipment capacity on a single project. Utilizing our various horizontal boring mills and large vertical boring mills, we were able to manufacture virtually every component in house, our welding department focused on the fabrication of various components and our millwrights assembled the entire product for immediate installation. When if was completed the manipulator arm was rated to lift up to 30,000 pounds at 20 feet from the fulcrum point, it is currently being used to load parts into ALCOA’s [now known as ARCONIC] 50,000 and 35,000 Ton presses to form components for the aerospace industry like bulkheads or fuselages.