Machining Services For Large, Long And Heavy Parts | Large Part Machining, Fabrication And Assembly Services For Manufacturing Companies In The U.S | Rates From $100 Per Hour

Precise Machining of Large, Long and Heavy Parts For Over 50 Years

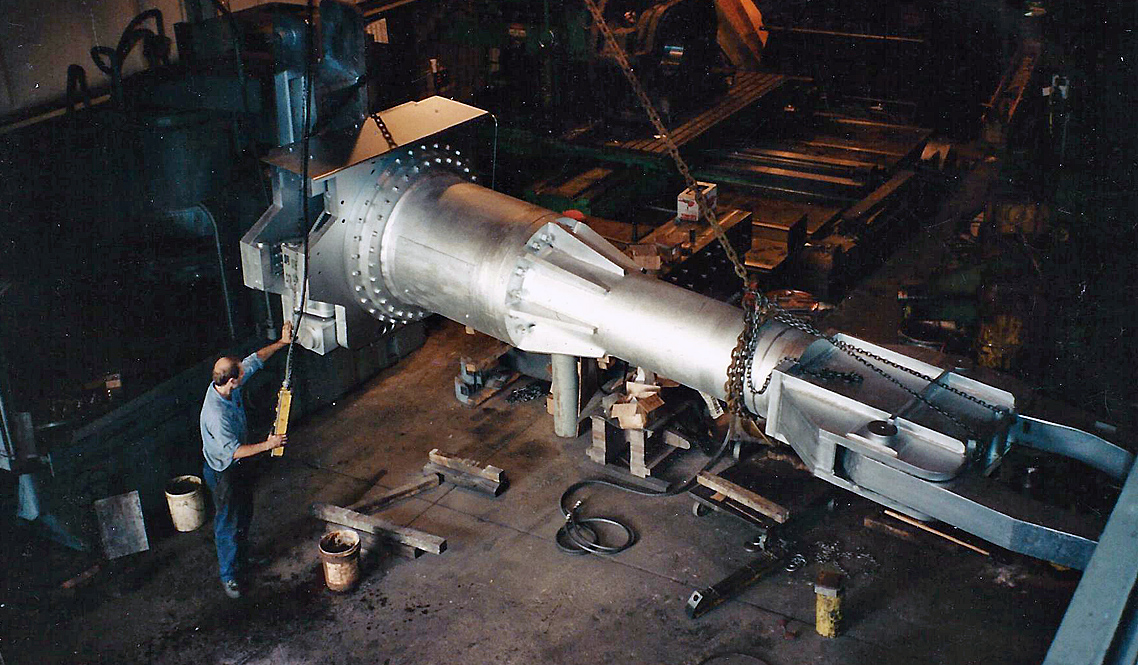

Kiefer Tool provides large part machining services for manufacturing and industrial firms throughout most of continental United States. Rates for machining large, big, long and heavy equipment components and massive workpieces start at $100 per hour. Due to our experience and our excellent equipment, we do high quality work on large diameter turning and large vertical turning/boring projects. We repair large hydraulic cylinders and fix hydraulic press components which keeps us busy with drilling, boring, grinding, milling, welding and fabrication processes. Not to get too technical, but Kiefer Tool also excels at 3 + 2 machining. We keep tight tolerances when performing precision CNC machining, keying and gear teeth cutting. We manufacture, fabricate and assemble enormous steel and metal parts and machines. The parts we machine frequently weigh a few hundred or a few thousand pounds, but we have the capacity and capabilities to handle parts that weigh up to 100 tons. Most of the parts we machine are for repair jobs, although we spend a fair amount of time in our large capacity machine shop manufacturing replacement parts for heavy equipment, large hydraulic presses and manufacturing machines. We also machine and manufacture “one-off” products, original equipment and prototypes. Shown below is a video that tours a large part machine shop and the different equipment and processes that go on at a large capacity machine shop.

About Kiefer Tool

Kiefer Tool & Mold Inc. is a job shop machine shop located in Cleveland Ohio that specializes in large part manufacturing and large capacity machining. The engineers at Kiefer Tool are considered to be some of the best in the large part machining industry. Customers include GE and Eaton. The skills sets of the machinists and equipment needed for large part machining is different than those of a typical job shop that focuses on more conventional sized parts. With our experienced staff of engineers, mill wrights and machinists we can disassemble, inspect and remanufacture components and complete machines. Large part welding and painting services are completed in-house. Shown below is a video that highlights numerous large part machining and manufacturing processes.

Overview Of Large Part Machining Services

Kiefer Tool machines and delivers large parts and components precisely, quickly and affordably. From turning large diameters to milling vast surface areas, our facility is equipped to handle a diverse field of large part machining. With both manual and CNC equipment for manufacturing large parts, we can manufacture all shapes and sizes, various alloy steels, and complex geometrical features. At Kiefer Tool & Mold Inc. we define large part machining to be over 200 lbs. in weight, over 6″ in diameter and greater than 2′ in length or width. Click here to view large part machining pictures. Our large capacity machine shop services include large part machining, large precision machining, heavy part machining, large CNC machining, large diameter machining, long turning capacities, horizontal boring and milling, threading, and keying. Kiefer Tool produces large part prototypes, large parts in small production runs and single highly complex component one-offs. Kiefer Tool is a large part production machine shop and contract manufacturing company that machines power transmission components (shafts, bushings, gears, pulleys, etc.), press frames, platens, hydraulic cylinders, fly wheels, pressure vessels, tanks, flanges, tie rods, and bolster plates, gear blanks, rolling mill components, hydraulic powered machines, aircraft components, mining equipment, railroad equipment, large cast parts, power generation equipment, petroleum and oil drilling equipment, construction equipment, and manufacturing equipment. Call 216-251-0076 or click here to request large part machining and turnings services and a quote.

Precise and Reliable Large Part Machining Services

We machine bulky and heavy manufacturing equipment parts and big fabrications that are too large for other machine shops to work on because small capacity machine shops don’t have adequately sized work zones, large part machining equipment or machine tools that are appropriate for large-scale parts. The engineers and machinists at Keifer Tool understand how the challenges of shifting workpiece temperature ranges and material stress affect the precise machining and finishing accuracy of large parts and components. Our large capacity machine shop was constructed with large part manufacturing in mind. Kiefer Tool uses jib cranes, gantry cranes and bridge cranes to move large and complex parts. Kiefer Tool also produces custom large and heavy, fully functional equipment and tool assemblies from ferrous and non-ferrous metals for manufacturing companies and OEMs located throughout the United States. Kiefer Tool also specializes in manufacturing, machining and repairing components of stamping presses such as bolster plates (large blocks of metal) which are attached on top of stamping press beds. For more information on the design and function of a bolster plate (or bed), click here.

Who We Serve And Where

Kiefer Tool provides large part machining services, primarily to medium to large scale manufacturing companies, although we also enjoy working with small family owned manufacturing businesses. Our engineers, machinists and mechanics spend most of their time repairing, rebuilding, maintaining, machining, manufacturing, fabricating, delivering and assembling large parts. Many of our firms operate hydraulic presses, which we repair, rebuild, manufacture and maintain on-site. We have a tendency to turn down offers to quote small part machining projects and normally leave the small stuff to competitors that don’t have a large capacity machine shop like ours. There are thousands of machine shops in the United States but only a handful of exceptional large part machining companies like Kiefer Tool.

While our engineers and mechanics normally machine large parts for customers in the Midwest, Mid-Atlantic, Northeast, Southeast and South Central regions of the United States, we occasionally do work for clients in the Southwest and Northwest. Most of our work comes from companies in the traditional manufacturing hubs such as the Rust Belt (Manufacturing Belt/Steel Belt/Factory Belt). These areas include Cleveland, Chicago, Buffalo, Milwaukee, Dayton, Gary (IN), Flint (MI) St. Louis, Columbus, Cincinnati, Akron, Toledo, Youngstown, the Pittsburgh-Lake Erie Region, the Detroit Industrial Region, the Lake Michigan Region, the Southern New England Region and the Southern Appalachian Region. We normally are not competitive on price, compared to local firms, when we quote large part machining services for firms in the West Region, Intermountain West Region and Pacific Coastal Region. Over the past 5 to 10 years, we have started accepting more large part machining services from firms in new areas of the United States where manufacturing is now thriving in 2019. The new manufacturing markets include Raleigh, the Omaha-Council Bluffs area, the Atlanta-Sandy Springs-Roswell region (GA), the Warren-Troy-Farmington Hills (MI) region, the Albany-Schenectady-Troy (NY) and Louisville.

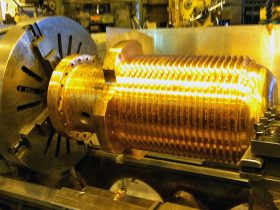

Boring, Turning, Grinding and Grooving

Kiefer Tool provides industry leading large part machining capabilities in milling, grinding, boring, turning and lathe services. Our machinists are capable of keeping tight tolerances when manufacturing extra large machined components. Our machining processes include line boring, large part vertical boring, large diameter turning, hydraulic cylinder boring, custom thread turning and grooving. Our vertical turning and milling center, large vertical gantry mills and lathe services are dedicated to large metal part machining, large diameter CNC turning, long turning, large diameter internal turning operations, threading, facing and boring.

Large Lathe Machining Services For U.S. Manufacturing Businesses And Heavy Industry Firms

Kiefer Tool does large lathe machining and metalworking for manufacturing companies that are located throughout the lower 48 states. Most of the large lathe machining work performed by Kiefer Tool is done for firms located in the “Rust Belt“. Our machinists do heavy duty lathe work, such as cutting and turning enormous workpieces, using large capacity Monarch lathes, industrial CNC lathes and manual South Bend lathes. We hold extremely tight tolerances when we machine long parts and large diameter industrial components. Our machinists are experts at machining and milling really hard metals and alloys precisely. Kiefer Tool’s large capacity machine shop is outfitted with various multi-spindle lathes, center lathes, Baileigh Industrial lathes, CNC turning centers, a Froriep vertical turret lathe, Bridgeport toolroom and metalworking lathes, Bolton bench top lathes and Swiss-style lathes.

Rush Jobs, Onsite Inspections and Repairs, Large Part Maintenance And Field Services

We can complete rush jobs and we keep tight delivery schedules. We provide emergency and “mission critical” equipment repair services. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. Rates start at $100. per hour.

Large Part Machining Service Areas In The United States

Kiefer Tool machines large parts (including hydraulic and manufacturing equipment components) for companies throughout the Midwest, the Middle Atlantic, the Northeast and portions of the Southern United States. We machine heavy and long parts for manufacturing companies in Cleveland, Columbus, Youngstown, Erie, Toledo, Akron, Cincinnati, Rochester (NY), Fort Wayne, Milwaukee, Pittsburgh, Detroit, Indianapolis, Chicago, Buffalo, Wheeling, St. Louis, Atlanta, Nashville, Knoxville, Lexington, Philadelphia, New York City, Boston, Raleigh, Omaha, Louisville, Albany, Baltimore, Huntsville (AL), Farmington Hills (MI), Minneapolis, Charlotte, Norfolk (VA), Kansas City, Grand Rapids (MI), Memphis and Allentown (PA).

We provide extremely precise, punctual and reliable large part machining services to industrial operations in Ohio, Pennsylvania, New York, West Virginia, Indiana, Michigan, West Virginia, Virginia, Connecticut, Rhode Island, Massachusetts, Vermont, Illinois, New Hampshire, Maine, Kentucky, Delaware, Maryland, New Jersey, North Carolina, South Carolina, Wisconsin, Minnesota, Iowa, Missouri, North Dakota, South Dakota, Nebraska, Tennessee and Kansas. We also have customers in northern Georgia, Alabama, Arkansas and Mississippi. Because of the prohibitive cost of shipping or transporting large parts and heavy manufacturing equipment components long distances, Kiefer Tool rarely serves companies located in the Western portion of the United States or the deep south. Due to the cost of travel, Kiefer Tool engineers and field service technicians don’t normally travel to the Western or Northwestern states to inspect large parts, hydraulic presses or other manufacturing machines.

Hydraulic Press and Hydraulic Cylinder Repair Services

If your company is considering scrapping a hydraulic press or hydraulic cylinder because the manufacturing company that built the press is no longer in business, or will not provide repair services, please talk to an engineer at Kiefer Tool first. We may be able to inspect your hydraulic press to see if it is worth repairing or rebuilding. We inspect crossheads, clevises, butt plates, mountings, clutch/brakes, seals, manifolds, beds, valves, flywheels, rams, moving platens, welded body cylinders, pumps, hydraulic pipes, hydraulic cylinders, lubrication systems, cylinder bases, trunnions, mechanical drives, bearings, robotic automation components, hydraulic fittings, subassemblies, master cylinders, pistons and piston rods, controls, electrical systems, cylinder barrels, flanges, cylinder heads, ports, dies and punches, tie rod cylinders, o-rings and other hydraulic press parts.

Additional Information About Large Part Machining and Large Part Repair Services

- Request A Quote For Large Part Machining Services

- Customers That Require Large Part Machining Services

- Large Part Machining Industry News

- Schedule a Part Pick Up or On-Site Field Inspection

- Emergency (Expedited Mission Critical Jobs) Large Part Machining and Repair Services

- Equipment Used to Machine And Fabricate Large Parts and Workpieces

- Getting Large Parts Machined Precisely, Quickly And Affordably

- Large Machine Shop Capacities in OH, IN, MI, NY And PA

- Request Large Part Machining and Turning Services And A Quote

- Submit a CAD Drawing, PDF or JPEG for a Large Part Machining Quote

- Large Diameter Machining, Vertical Boring & Turning

- Rebuilding Hydraulic Presses

- Hydraulic Press Repair, Maintenance, Inspections, Field Services

- Custom Hydraulic Cylinder Manufacturing And Repair

- Hydraulic and Mechanical and Press & Component Manufacturing

- Hydraulic Press, Component and Equipment Repair

Contact Kiefer Tool To Request A Quote For Large Part Machining Services

- Call (216) 251-0076 for a Quote

- To Submit an RFQ, CAD Drawing or P.O. Click Here or Email info@kiefertool.com

- Large Part Machining, Large Diameter Turning, Large CNC Machining, Large Plate Machining and Large Precision Machining Services Range in Price from $100.00 to $150.00 per hour. Click Here for More Information on our Large Part Machining Rates. For ballpark prices for machining specific types of large parts, click here.

SERVICE DETAILS

The following are some of the operations and equipment we use to conduct our Large Part Machining services.