Overview of Equipment Used For Machining and Fabricating Large/Heavy Parts, Workpieces and Manufacturing/Industrial Equipment Components

Overview of Equipment Used For Machining and Fabricating Large/Heavy Parts, Workpieces and Manufacturing/Industrial Equipment Components

- A Flexible, Large Square Foot Machine Shop With A High Ceiling

- Specialized Equipment For Moving Large Parts And Workpieces Including Forklifts, Hoists, Overhead Cranes And Rigging Hardware

- Large Horizontal And Vertical Milling Centers And Machines

- Large Horizontal And Vertical Boring Machines Including Large Drilling Machines

- Large Vertical Turning Mills, Lathes, Centers and Machines

- Bridge Mills And Planers

- Key Way Broaching And Shaper Machines

- Large Surface Grinding Equipment

- CNC Controlled Machines Such As Machining Centers

- Various Carbide And High Speed Steel Cutting Tools Such As End Mills, Facing Mills And Grooving Tools

- Testing And Inspection Equipment

- Welding Equipment

- Layout And Positioning Equipment

- Manufacturing Facility Thermal Control Systems

- Machining Lubricants And Metal Working Fluids

Overview of Large Capacity Machine Shops

Large scale welding and fabrication services are also provided by job shops that can handle large projects and large workpieces. The three principal machining processes employed by large capacity machine shops are classified as milling, boring (drilling) and turning. Large capacity CNC machines are frequently used to manage the operation and movement of the lathes, cutting machines and boring mills. These shops use extremely large CNC machines, lathes, mills and equipment to machine really big and complex steel, metal and alloy parts. Other services provided by custom large component manufacturing companies include burning, heat treating, reaming, steel cutting, shearing, shaping, electroplating fabrication, inspection, painting and assembly. Large capacity machines shops provide both production and prototype parts. Machinists at these large capacity shops use large machines and tools to perform large diameter turning, boring, precision tapping, planing, grooving, vertical, horizontal, and angled surface machining. Large capacity machine shops typically work with materials such as steel, metal, metal alloys and rarely plastics and composites. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. We provide on-site field inspections for many types of industrial manufacturing equipment and machinery. Rates start at $100. per hour.

To Request A Quote For Large Part or Large Component Machining and Fabrication Services

- Call (216) 251-0076 for a Quote

- To Submit an RFQ, CAD Drawing or P.O. Click Here or Email info@kiefertool.com

- Click Here for More Information on our Large Part Machining Rates

Equipment And Machines Used During The Process of Machining Large Steel and Metal Parts and Components

A Flexible, Large Square Foot Machine Shop With A High Ceiling

- Machines set up in a machine cell environment

- Large bay doors or loading Docks

- 8 foot wide walk ways

- 15-20 feet of working area below crane bridges

- 480 volt electrical capacities

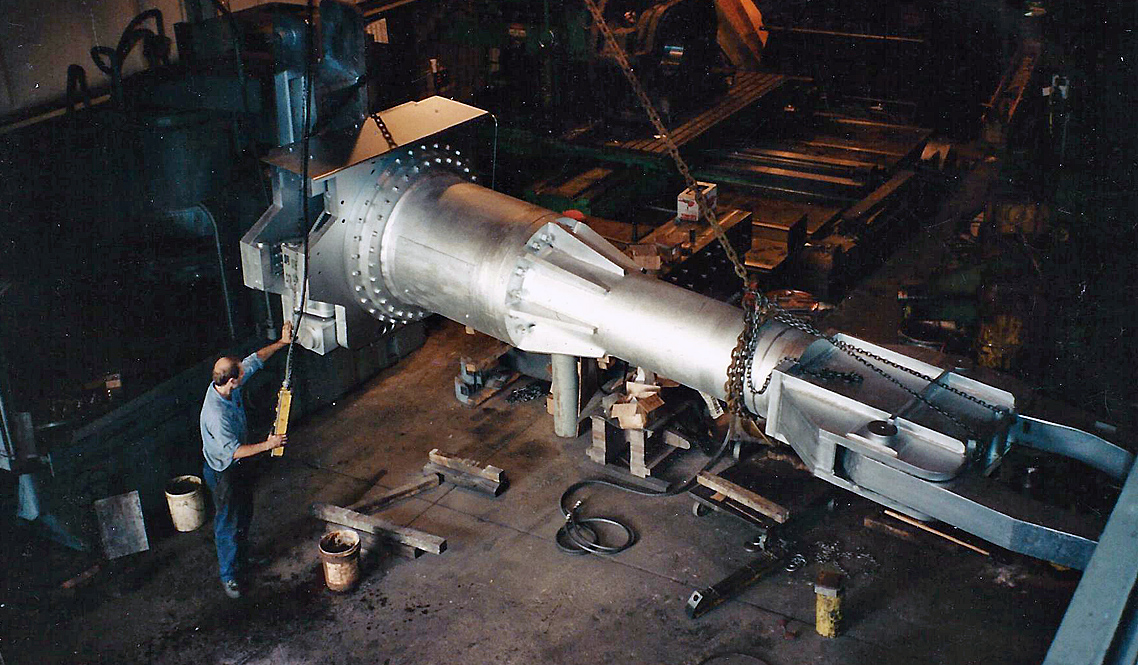

Specialized Equipment For Moving Large Parts And Workpieces Including Forklifts, Hoists, Overhead Cranes And Rigging Hardware

Large capacity machines shops generally use large hoists (5 tons or more) and cranes that can handle parts up to 60,000 pounds or more. These hoists often run the length of the manufacturing facility which allow the machine shop employees to move really big and heavy parts around the plant. Cranes with at least 24 feet under the bridge also enable a large capacity machine shop to work on enormous parts. Forklifts or lift trucks also come in handy at large capacity machine shops, manufacturing factories and warehouses for moving heavy parts and components.

- Mitsubishi Forklifts and Lift Trucks, Cat Lift Trucks and Towmotors

- EMH overhead bridge cranes

- Gantry cranes

- Wall traveling jib cranes

- Hand chain, electric, mini puller, lever and trolley hoists

- Rigging hardware

- Industrial man lifts, maintenance platforms, heavy duty ladders and material handling systems and equipment

- 10-100 Ton Hydraulic Jacks

Large Horizontal and Vertical Boring Machines and Milling Centers

- Vertical double column bridge mills

- DeVlieg boring mills

- Giddings & Lewis (G&L) Horizontal Boring Mills

- Lucas Horizontal Boring Mills

- Mitsubishi Floor Type Horizontal Boring Mill MAF-R Series

- Pratt & Whitney Jig Borer Rotary and Milling Tables

- Single point and multiple-cutting-edge tools

- Wotan boring mills

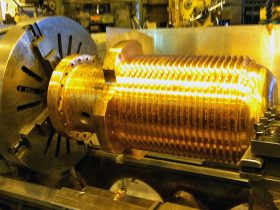

Large Vertical Turning Mills, Lathes, Centers and Machines

- Bullard vertical turning lathes

- Large-Capacity Doosan Vertical Turning Lathes

- Old Warner and Swasey turret lathes (Warner & Swasey’s last operating plant in Solon, Ohio closed in January of 1992)

- Multi-Axis turning/milling lathes made by Chevaller Machinery, Inc.

- Lathes from Monarch Lathes

- Single point and multiple-cutting-edge tools

- Straight turning, contour turning, form turning and taper turning equipment

- Bar feeders

- Okuma LU7000EX 2-Saddle CNC Lathe

- Mazak CNC lathes with Fanuc controls

- Clausing large swing lathes

- Thread turning inserts, multi-tooth inserts and toolholder systems

- DMG MORI NTX Series Turn-Mill Machines

Key Way Broaching Machines and Shapers

- Mitts & Merrill keyseating machines, slotting machines, broaching machines and profiling machines

- Rockford Slotters

Bridge Mills and Planers

- Large vertical gantry mills (Some have right angle and universal heads and spindle extensions)

- Planer Mills

- 5-Face travelling gantry rail type milling machines

Large Surface Grinding Equipment

- Blanchard surface grinding machines

- Norton Cylindrical Grinders

- Mattison Reciprocating Grinder

CNC Controlled Machines

- Milling and turning centers

- Large horizontal machining centers

- Mitsubishi vertical bridge mills

- Multi-axis machines

- Multitasking machines

- CNC 5-axis mills

- 5-Axis, 4-axis and single-setup 3+2-axis cutting and drilling tools

- Robotics: Twin spindles and robotic gantry loading lathes

- Large CNC machining equipment

Various Carbide and High Speed Steel Cutting Tools

- Kennametal Metal Working Tools, Carbide Inserts and Cutting Tools

- End Mills

- Grooving Tools

- Koroy Face Mill Sets

- Spade Drills

- Hertel Drill Bits

Heat Treating And Annealing Equipment

- Temperature Controlled Furnaces

- Propane or Acetylene Torches and Burners

Testing and Inspection Equipment

- Inspection and testing equipment

- Large Mitutoyo and Starrett micrometers

- Large vernier calipers

- Height gauges

- Gauge (Jo) blocks

- Weld crack detection kits, dye penetrants and inspection kits

Welding, Fabricating and Conditioning Equipment

- Burning equipment including oxy-fuel burners and laser burners

- Welding equipment including robotic welding equipment

- Saws and cold saws

- Drill presses and hydraulic presses

- Large plate machining equipment

- Large weldment machining equipment

- Assembly equipment

- Hand tools

- Parts washer and kerosene tanks

- Sand and dry ice blasting equipment for cleaning large parts and components

- Painting equipment

- Foundations for machine tools

Layout Equipment and Positioning Equipment

- Large layout tables

- Workpiece positioning equipment

- Headstock and tailstock positioners

- Robotic positioners

- Welding positioners

Thermal Control Systems For Large Part Machining And Manufacturing Facilities

- Work Piece temperature control systems

- Active and passive cooling systems to ensure precise tolerances due to expansion and contraction of metal

Machining Lubricants And Metal Working Fluids

- Tapping compounds

- Starcool grinding fluids

- Stainless steel cutting oils

- Kerosene for aluminum and magnesium

Featured Large Machine Shops and Large Part Fabricators

Dowding Machining

Overview: Companies such as Dowding Machining in Eaton Rapids, Michigan have equipment capable of machining very large parts. They provide precision machining solutions for large components. The largest machine in the shop, a MAG Cincinnati U5 profiler, features not just 100 feet of X-axis travel, but also travels of 12 feet in Y. Some jobs call upon much of that Y-axis span. The firm machines castings for wind-turbine gearbox sections.

Mazak Corporation

Overview: The Mazak Corporation is a global machine tool supplier. Their North American headquarters and manufacturing campus is located in Florence, Kentucky. They sell and service really big machines. The company uses its own equipment to produce machine tools. Learn how they machine really big parts on a large five-axis machining center. Large part machining companies like Kiefer Tool and Mold of Cleveland, purchase bigger machines from Mazak Corporation so that they can increase the size of the parts they can repair and manufacture. Some parts that are machined using large part machining equipment from Mazak can weigh as much as a small car.

K & M Machine-Fabricating, Inc.

K & M is a contract manufacturing company located in Cassopolis, MI. Their company produces large machined parts and large fabrications. K&M is ISO 9001:2015 certified. K&M consists of a 3 building complex located on 92 acres. K&M’s operates 378,000 square-foot manufacturing facilities. K&M Machine-Fabricating specializes in large machined and fabricated parts up to 100 tons. K & M Machine-Fabricating, Inc. established a scholarship program in 2001 in recognition of K & M’s 50th anniversary and in honor of the entrepreneurial spirit of its founder, Mr. Earl G. Marhanka. To date, over $220,000 has been awarded to 56 sons and daughters of K & M employees who meet the program requirements.

Makino Milling Machine Co., Ltd.

Commonly known as Makino, is a machine tool builder with global sales and service, headquartered in Japan. Makino was established in 1937 by Tsunezo Makino in Japan, developing Japan’s first numerically controlled (NC) milling machine in 1958 and Japan’s first machining center in 1966. Companies such as Covert Manufacturing located in Galion, Ohio purchased their first Makino machines in the 1970s. Covert Manufacturing is a $50-million-per-year production machining company that has experienced significant growth. Makino specializes in manufacturing machine tools such as 4 and 5 axis horizontal machining centers, graphite machining centers and vertical machining centers.

Rush Jobs, Onsite Inspections and Repairs, Large Part Maintenance And Field Services

We can complete large part machining jobs in a hurry. We keep tight delivery schedules. We provide emergency and “mission critical” equipment repair services. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. Rates start at $100. per hour.

Large Part Machining Service Areas In The United States

Kiefer Tool machines large parts (including hydraulic and manufacturing equipment components) for companies throughout the Midwest, the Middle Atlantic, the Northeast and portions of the Southern United States. We machine heavy and long parts for manufacturing companies in Cleveland, Columbus, Youngstown, Erie, Toledo, Akron, Cincinnati, Rochester (NY), Fort Wayne, Milwaukee, Pittsburgh, Detroit, Indianapolis, Chicago, Buffalo, Wheeling, St. Louis, Atlanta, Nashville, Knoxville, Lexington, Philadelphia, New York City, Boston, Raleigh, Omaha, Louisville, Albany, Baltimore, Huntsville (AL), Farmington Hills (MI), Minneapolis, Charlotte, Norfolk (VA), Kansas City, Grand Rapids (MI), Memphis and Allentown (PA).

We provide extremely precise, punctual and reliable large part machining services to industrial operations in Ohio, Pennsylvania, New York, West Virginia, Indiana, Michigan, West Virginia, Virginia, Connecticut, Rhode Island, Massachusetts, Vermont, Illinois, New Hampshire, Maine, Kentucky, Deleware, Maryland, New Jersey, North Carolina, South Carolina, Wisconsin, Minnesota, Iowa, Missouri, North Dakota, South Dakota, Nebraska, Tennessee and Kansas. We also have customers in northern Georgia, Alabama, Arkansas and Mississippi. Because of the prohibitive cost of shipping or transporting large parts and heavy manufacturing equipment components long distances, Kiefer Tool rarely serves companies located in the Western portion of the United States or the deep south. Due to the cost of travel, Kiefer Tool engineers and field service technicians don’t normally travel to the Western or Northwestern states to inspect large parts, hydraulic presses or other manufacturing machines.

Hydraulic Press and Hydraulic Cylinder Repair Services

If your company is considering scrapping a hydraulic press or hydraulic cylinder because the manufacturing company that built the press is no longer in business, or will not provide repair services, please talk to an engineer at Kiefer Tool first. We may be able to inspect your hydraulic press to see if it is worth repairing or rebuilding. We inspect crossheads, clevises, butt plates, mountings, clutch/brakes, seals, manifolds, beds, valves, flywheels, rams, moving platens, welded body cylinders, pumps, hydraulic pipes, hydraulic cylinders, lubrication systems, cylinder bases, trunnions, mechanical drives, bearings, robotic automation components, hydraulic fittings, subassemblies, master cylinders, pistons and piston rods, controls, electrical systems, cylinder barrels, flanges, cylinder heads, ports, dies and punches, tie rod cylinders, o-rings and other hydraulic press parts.

Additional Information About Large Part Machining and Large Part Repair Services

- Request A Quote For Large Part Machining Services

- Customers That Require Large Part Machining Services

- Large Part Machining Industry News

- Schedule a Part Pick Up or On-Site Field Inspection

- Emergency (Expedited Mission Critical Jobs) Large Part Machining and Repair Services

- Getting Large Parts Machined Precisely, Quickly And Affordably

- Large Machine Shop Capacities in OH, IN, MI, NY And PA

- Request Large Part Machining and Turning Services And A Quote

- Submit a CAD Drawing, PDF or JPEG for a Large Part Machining Quote

- Large Diameter Machining, Vertical Boring & Turning

- Rebuilding Hydraulic Presses

- Hydraulic Press Repair, Maintenance, Inspections, Field Services

- Custom Hydraulic Cylinder Manufacturing And Repair

- Hydraulic and Mechanical and Press & Component Manufacturing

- Hydraulic Press, Component and Equipment Repair

To Request A Quote For Large Part or Large Component Machining and Fabrication Services

- Call (216) 251-0076 for a Quote

- To Submit an RFQ, CAD Drawing or P.O. Click Here or Email info@kiefertool.com

- Click Here for More Information on our Large Part Machining Rates

SERVICE DETAILS

The following are some of the operations and equipment we use to conduct our Large Part Machining services.