Assembly Services at Kiefer Tool & Mold

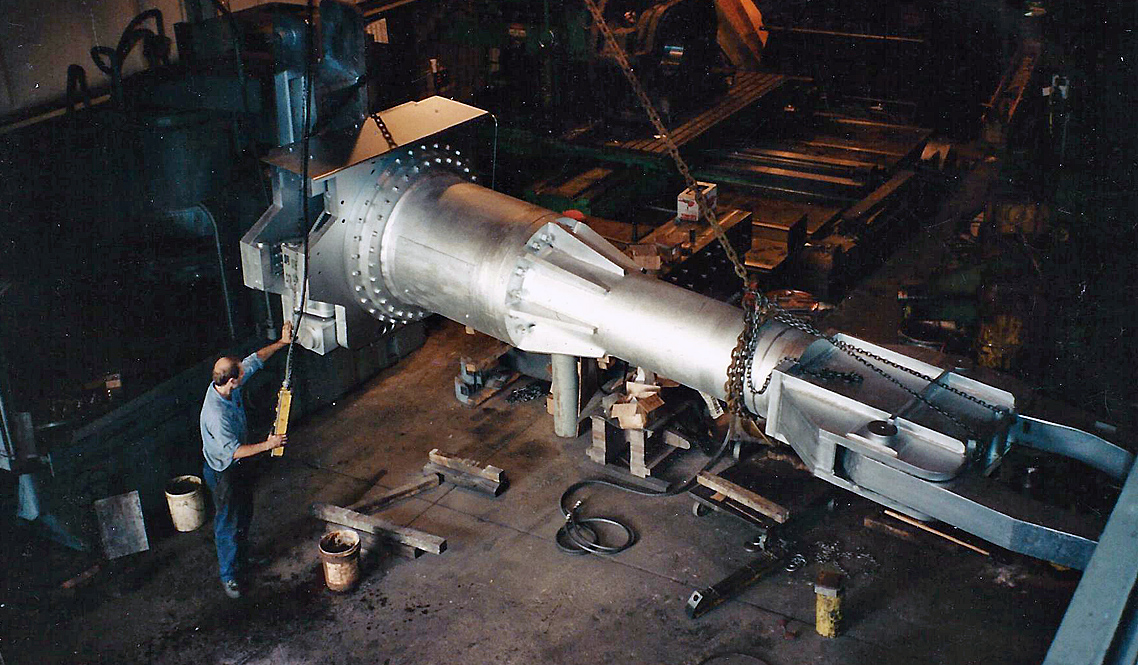

Kiefer Tool provides assembly services for hydraulic, manufacturing and industrial equipment and machines that we have repaired, retrofitted or reconditioned. Part of the services that Kiefer Tool and Mold provide for the repair/reconditioning or retrofitting of your manufacturing and industrial equipment is their assembly upon completion. With our experienced staff and wide range of equipment capacity we are capable of creating a ready for installation product. Also encompassing the disassembly of a product for repair or reconditioning, our services would include the inspection of the product to ensure its quality and proper function. Our facility is outfitted with a 30 ton crane with 26 feet below the bridge to handle large assemblies, a 150 ton press for bushing and bearing assembly along with a 100 ton gear puller for disassembly of gear boxes. In addition to our complete machine shop we also provide welding and some fabricating services as well. Kiefer Tool specializes in large part machining and custom hydraulic cylinder manufacturing. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. We provide on-site field inspections for many types of industrial manufacturing equipment and machinery. Rates start at $100. per hour. To learn more about the types of equipment used to assemble large manufacturing machines and large components, click here.

- Call (216) 251-0076 for a Quote

- To Submit an RFQ, CAD Drawing or P.O. Click Here or Email info@kiefertool.com

- Manufacturing and Industrial Machine Assembly Services Range in Price from $75.00 to $150.00 per hour. Click Here for More Information on our Equipment Assembly Rates.