Kiefer Tool Customers That Require Large Part Machining Services

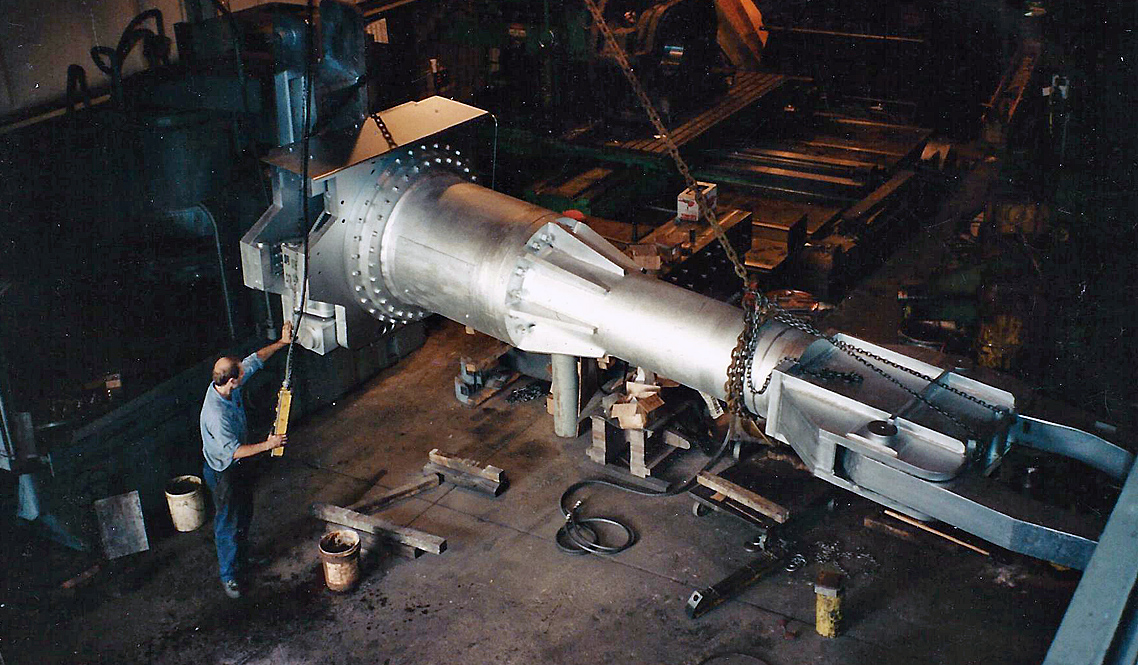

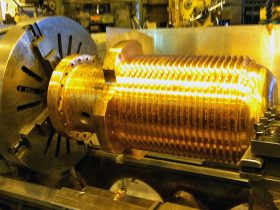

Kiefer Tool provides large part machining and large part manufacturing services to customers in the manufacturing and industrial industries throughout the United States. Kiefer Tool is a contract manufacturing company that machines, fabricates and manufactures big, heavy, complex and large parts and components that conform to our customer’s exact specifications. Clients usually provide the Kiefer engineers with a CAD drawing so that Kiefer machinists can keep very tight tolerances. Kiefer Tool produces large-scale parts that typically exceed their customer’s expectations, demands and requirements in terms of durability, turnaround times, costs, quality and machining tolerances. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. We provide on-site field inspections for many types of industrial manufacturing equipment and machinery. Rates start at $100. per hour.

Companies And Customers We Have Served

- Eaton for their Air Flex Product Line

- General Electric

- Saint-Gobain

- Vecoplan

- Ferrous Metal Processing

- Horsburgh & Scott

- Alpha Packaging

- Aetna Plastics Corp.

Rush Jobs, Onsite Inspections and Repairs, Large Part Maintenance And Field Services

We can complete large part machining jobs in a hurry. We keep tight delivery schedules. We provide emergency and “mission critical” equipment repair services. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. Rates start at $100. per hour.

Large Part Machining Service Areas In The United States

Kiefer Tool machines large parts (including hydraulic and manufacturing equipment components) for companies throughout the Midwest, the Middle Atlantic, the Northeast and portions of the Southern United States. We machine heavy and long parts for manufacturing companies in Cleveland, Columbus, Youngstown, Erie, Toledo, Akron, Cincinnati, Rochester (NY), Fort Wayne, Milwaukee, Pittsburgh, Detroit, Indianapolis, Chicago, Buffalo, Wheeling, St. Louis, Atlanta, Nashville, Knoxville, Lexington, Philadelphia, New York City, Boston, Raleigh, Omaha, Louisville, Albany, Baltimore, Huntsville (AL), Farmington Hills (MI), Minneapolis, Charlotte, Norfolk (VA), Kansas City, Grand Rapids (MI), Memphis and Allentown (PA).

We provide extremely precise, punctual and reliable large part machining services to industrial operations in Ohio, Pennsylvania, New York, West Virginia, Indiana, Michigan, West Virginia, Virginia, Connecticut, Rhode Island, Massachusetts, Vermont, Illinois, New Hampshire, Maine, Kentucky, Deleware, Maryland, New Jersey, North Carolina, South Carolina, Wisconsin, Minnesota, Iowa, Missouri, North Dakota, South Dakota, Nebraska, Tennessee and Kansas. We also have customers in northern Georgia, Alabama, Arkansas and Mississippi. Because of the prohibitive cost of shipping or transporting large parts and heavy manufacturing equipment components long distances, Kiefer Tool rarely serves companies located in the Western portion of the United States or the deep south. Due to the cost of travel, Kiefer Tool engineers and field service technicians don’t normally travel to the Western or Northwestern states to inspect large parts, hydraulic presses or other manufacturing machines.

Hydraulic Press and Hydraulic Cylinder Repair Services

If your company is considering scrapping a hydraulic press or hydraulic cylinder because the manufacturing company that built the press is no longer in business, or will not provide repair services, please talk to an engineer at Kiefer Tool first. We may be able to inspect your hydraulic press to see if it is worth repairing or rebuilding. We inspect crossheads, clevises, butt plates, mountings, clutch/brakes, seals, manifolds, beds, valves, flywheels, rams, moving platens, welded body cylinders, pumps, hydraulic pipes, hydraulic cylinders, lubrication systems, cylinder bases, trunnions, mechanical drives, bearings, robotic automation components, hydraulic fittings, subassemblies, master cylinders, pistons and piston rods, controls, electrical systems, cylinder barrels, flanges, cylinder heads, ports, dies and punches, tie rod cylinders, o-rings and other hydraulic press parts.

Additional Information About Large Part Machining and Large Part Repair Services

- Request A Quote For Large Part Machining Services

- Large Part Machining Industry News

- Schedule a Part Pick Up or On-Site Field Inspection

- Emergency (Expedited Mission Critical Jobs) Large Part Machining and Repair Services

- Equipment Used to Machine And Fabricate Large Parts and Workpieces

- Getting Large Parts Machined Precisely, Quickly And Affordably

- Large Machine Shop Capacities in OH, IN, MI, NY And PA

- Request Large Part Machining and Turning Services And A Quote

- Submit a CAD Drawing, PDF or JPEG for a Large Part Machining Quote

- Large Diameter Machining, Vertical Boring & Turning

- Rebuilding Hydraulic Presses

- Hydraulic Press Repair, Maintenance, Inspections, Field Services

- Custom Hydraulic Cylinder Manufacturing And Repair

- Hydraulic and Mechanical and Press & Component Manufacturing

- Hydraulic Press, Component and Equipment Repair

SERVICE DETAILS

The following are some of the operations and equipment we use to conduct our Large Part Machining services.