Industrial Machine Repair at Kiefer Tool & Mold Inc.

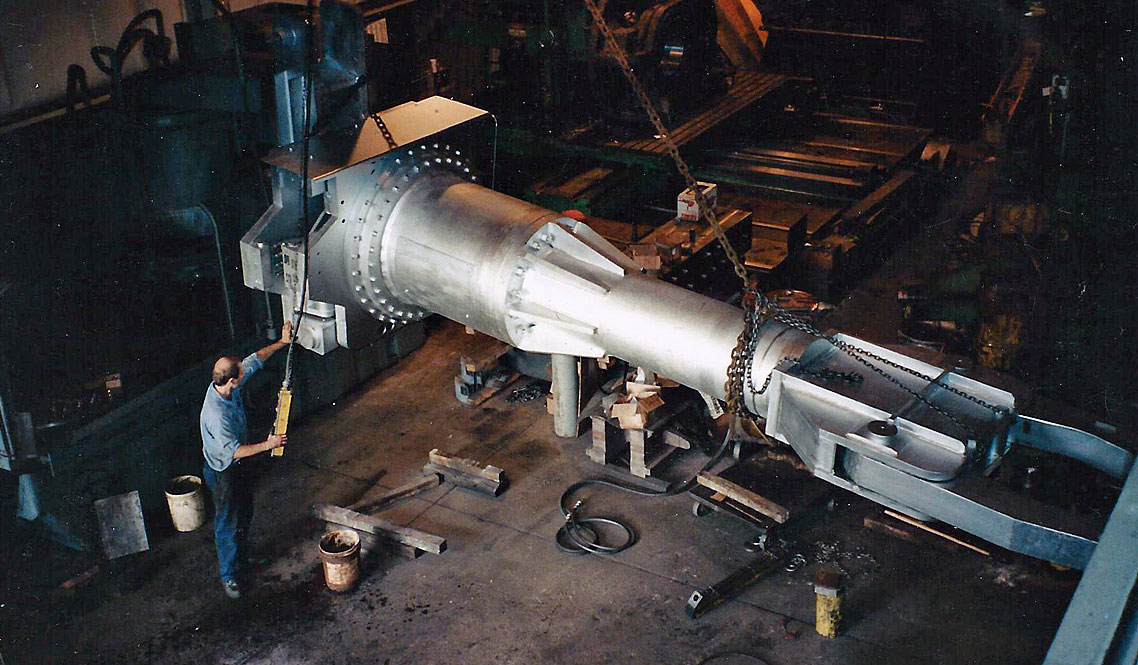

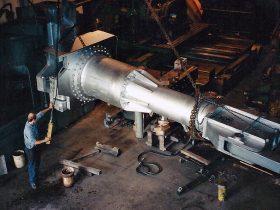

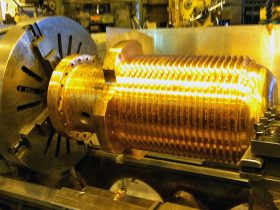

Kiefer Tool and Mold repairs, rebuilds and reconditions hydraulic cylinders and assemblies, spindles, hydraulic and mechanical presses, stamping presses, tool and dies, bolt making machines, injection mold machines, shafts, bushings, mold and die assemblies, fly wheels, gear boxes, injection cylinders and plunger screws, injection and ejector plates, material hopper assemblies, feed rolls, die cases, armatures bearings and manufacturing equipment components and parts. Our machining company has over 50 years of experience in the manufacturing industry, and in that time has developed processes that allow us to be precise, efficient and cost effective in the repairing of industrial machines and equipment. The years of experience have exposed our engineering staff to all kinds of different equipment and machines, along with various component applications and designs. With a large capacity machine shop, welding department, hydraulic equipment and a 30 ton crane; our facility is outfitted to repair, retrofit, and recondition industrial machines of all shapes, sizes and quantities. Kiefer Tool provides manufacturing companies with hydraulic press repair, hydraulic press maintenance, on-site inspections, on-site repairs, technical support and field services. We provide on-site field inspections for many types of industrial manufacturing equipment and machinery. Rates start at $100. per hour.

Kiefer Tool also specializes in manufacturing, machining and repairing components of stamping presses such as bolster plates (large blocks of metal) which are attached on top of stamping press beds. For more information on the design and function of a bolster plate (or bed), click here.

Industrial Machine Repair Service Areas

Kiefer Tool repairs and rebuilds hydraulic presses and manufacturing equipment for companies throughout the Midwest, the Middle Atlantic, the Northeast and portions of the Southern United States. We repair equipment for manufacturing companies in Cleveland, Columbus, Youngstown, Erie, Toledo, Akron, Cincinnati, Rochester (NY), Fort Wayne, Milwaukee, Pittsburgh, Detroit, Indianapolis, Chicago, Buffalo, Wheeling, St. Louis, Atlanta, Nashville, Knoxville, Lexington, Philadelphia, New York City, Boston, Raleigh, Omaha, Louisville, Albany, Baltimore, Huntsville (AL), Farmington Hills (MI), Minneapolis, Charlotte, Norfolk (VA), Kansas City, Grand Rapids (MI), Memphis and Allentown (PA).

We repair hydraulic presses and manufacturing equipment for industrial operations in Ohio, Pennsylvania, New York, West Virginia, Indiana, Michigan, West Virginia, Virginia, Connecticut, Rhode Island, Massachusetts, Vermont, Illinois, New Hampshire, Maine, Kentucky, Delaware, Maryland, New Jersey, North Carolina, South Carolina, Wisconsin, Minnesota, Iowa, Missouri, North Dakota, South Dakota, Nebraska, Tennessee and Kansas. We also have customers in northern Georgia, Alabama, Arkansas and Mississippi. Because of the prohibitive cost of shipping or transporting large hydraulic parts and equipment long distances, Kiefer Tool rarely serves companies located in the Western portion of the United States or the deep south. Due to the cost of travel, Kiefer Tool engineers and field service technicians don’t normally travel to the Western or Northwestern states.

Additional Information About Industrial Machine Repair Services

- Request A Quote For Large Part Machining Services

- Customers That Require Large Part Machining Services

- Large Part Machining Industry News

- Schedule a Part Pick Up or On-Site Field Inspection

- Emergency (Expedited Mission Critical Jobs) Large Part Machining and Repair Services

- Equipment Used to Machine And Fabricate Large Parts and Workpieces

- Getting Large Parts Machined Precisely, Quickly And Affordably

- Large Machine Shop Capacities in OH, IN, MI, NY And PA

- Request Large Part Machining and Turning Services And A Quote

- Submit a CAD Drawing, PDF or JPEG for a Large Part Machining Quote

- Large Diameter Machining, Vertical Boring & Turning

- Rebuilding Hydraulic Presses

- Hydraulic Press Repair, Maintenance, Inspections, Field Services

- Custom Hydraulic Cylinder Manufacturing And Repair

- Hydraulic and Mechanical and Press & Component Manufacturing

- Hydraulic Press, Component and Equipment Repair

Contact Kiefer Tool For Industrial and Manufacturing Machine Repair Services

- Call (216) 251-0076 for a Quote

- To Submit an RFQ, CAD Drawing or P.O. Click Here or Email info@kiefertool.com

- Industrial machine repair services range in cost from $75.00 to $150.00 per hour. Click Here for more information on repair and machining prices.

SERVICE DETAILS

The following list contains a few examples of machines or components we repair for industrial equipment, for a complete detail of our facility’s capacity please check out our machining page here .